- The Company

- Articles

- Coalescer Gas Liquid Separator Designs

- Comparison of Centrifugal and Vane Style Gas Liquid Separators

- Design & Capabilities of Gas Liquid Separators

- Differences of a Knock-Out Drum and Centrifugal Gas-Liquid Separator

- Exhaust Head Design

- How float drain traps work, installation and maintenance

- How to identify a Wright-Ausin Separator

- How to Size a Moisture Separator

- Steam Traps vs. Steam Separators

- Efficiencies of Centrifugal Separators

- Understanding Sizing Factors For Gas/Liquid Separators

- Horizontal

- Vertical

- High Solids

- Coalescer

- Elements

- Exhaust Heads

- Float drain traps

- Liquid level gauges

- Sizing Calculators

- Inquiries

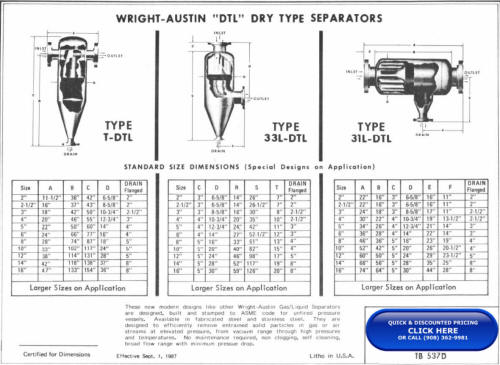

T-DTL, 31L-DTL and 33L-DTL Gas Liquid Separators

Separation of high solid, sludgy gasses down to >10 microns

Wright-Austin high efficiency DTL

gas liquid separators for horizontal or vertical down-flow

applications are designed specifically for non-liquid particle

separation or more commonly, separation of liquids containing a high

percentage of solids resulting in sludge-like flow to drain from the

system. The conical shaped drain sump of DTL gas

liquid separators ensure drainage of slurry-like fluids.

View our article describing this design in more detail with

application descritpions.

Wright-Austin high efficiency DTL

gas liquid separators for horizontal or vertical down-flow

applications are designed specifically for non-liquid particle

separation or more commonly, separation of liquids containing a high

percentage of solids resulting in sludge-like flow to drain from the

system. The conical shaped drain sump of DTL gas

liquid separators ensure drainage of slurry-like fluids.

View our article describing this design in more detail with

application descritpions.

When properly sized, Wright-Austin DTL separators will remove up to 99% of all liquid and solids greater than 10 microns in size from an air, steam or industrial gas flow. The removal is accomplished by a design that causes the air/gas/steam to enter into controlled centrifugal vortex which forces the entrained material to the outer wall (vessel ID). A vortex containment plate (VCP) prevents re-entrainment of the separated liquid and particles. The removed particles and liquid accumulate at the bottom of the conical drain sump.

DTL separators are sometimes used to recover or separate the desired material from the gas stream. A float style drain trap is not recommended for removal of the separated material because solids clog-up this type of valve. We typically suggest using a rotary valve because it is designed to handle slurries with minimal loss of air, gas or steam from the system.

All Wright-Austin DTL style gas liquid separators are available with ASME code stamp in accordance with ASME Section VIII, Division I and can be assigned a Canadian Registration Number (CRN).

| DTL Separator Applications: | |||

|

• Steam Drums |

• Gas Well Heads |

• Scrubbing Systems |

• Mist Elimination |

Outline Drawings