- The Company

- Articles

- Coalescer Gas Liquid Separator Designs

- Comparison of Centrifugal and Vane Style Gas Liquid Separators

- Design & Capabilities of Gas Liquid Separators

- Differences of a Knock-Out Drum and Centrifugal Gas-Liquid Separator

- Exhaust Head Design

- How float drain traps work, installation and maintenance

- How to identify a Wright-Ausin Separator

- How to Size a Moisture Separator

- Steam Traps vs. Steam Separators

- Efficiencies of Centrifugal Separators

- Understanding Sizing Factors For Gas/Liquid Separators

- Horizontal

- Vertical

- High Solids

- Coalescer

- Elements

- Exhaust Heads

- Float drain traps

- Liquid level gauges

- Sizing Calculators

- Inquiries

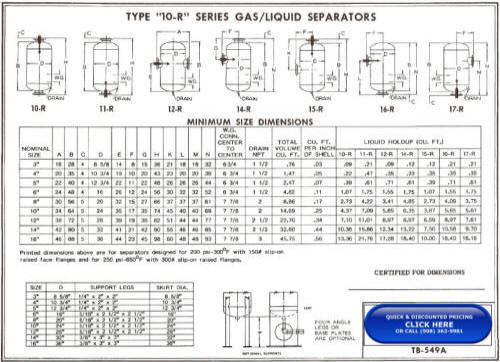

Wright-Austin R Gas Liquid Separators

Receiver Style Separators for High Liquid Loads

Wright-Austin R style air/liquid separators are the most complex type T centrifugal separator design offered, designed specifically to handle liquid "slugs" or heavy liquid loads. The creation of a powerful vortex and centrifugal separation is the same as the other designs; where the Receiver (R) style differs is its large reservoir and dual vortex chamber design. The type R separator can separate a higher liquid load then hte other type T designs or it can be used in lieu of a type T or TS to minimize the physical diameter and length of the vessel when the installation footprint needs to be minimized. Whereas a Type T separator has a liquid removal capacity equivalent to 40% of its maximum rated capacity, Type R separators increase this to 90%.

The entrained liquid within the gas entering Type R separators impinges upon an angled surface and into a tangential downwards swirl. Coalescing of droplets from impingement on the plate and vessel walls collect at the bottom of the separator and drain port.

The exit path is located at the top of the vessel, thus the gas passes through an angled separation element and only the finer droplets pass through it without impinging on the exterior separation element. The angled entrance into the separation chamber creates a powerful vortex and the resulting centrifugal force propels droplets and particles larger than 10 microns outwards toward the lower section of the separation element where they coalesce to a drain pipe having its exit near the main separator drain port. The exit nozzle protrudes into the low velocity section of the separation vortex where only droplets smaller than 10 microns can pass, so the resulting dry, clean gas flows upwards and exits through the outlet of the separator. The separation is accomplished without complex baffles, deflectors and other structures that obstruct the flow-stream and this results in very low pressure drops compared to other designs such as vane style separators. Type R separators remove entrained droplets larger than 10 microns with 99% efficiency, having no internal moving or serviceable components; they are a fully welded pressure vessel requiring no maintenance for the service lifetime. R style gas/liquid separators are fabricated from carbon steel, 304SS, 316SS and can also be fabricated from exotic alloys as needed. An ASME code stamp and CRN can also be provided.

Applications include:

-

Refineries and other chemical process applications

-

Flash or surge tanks

-

Scrubber and demisting ahead of a steam turbines

Wright-Austin Type Receiver ("R") Gas Liquid Separator Drawings (Click to open PDF file)