- The Company

- Articles

- Coalescer Gas Liquid Separator Designs

- Comparison of Centrifugal and Vane Style Gas Liquid Separators

- Design & Capabilities of Gas Liquid Separators

- Differences of a Knock-Out Drum and Centrifugal Gas-Liquid Separator

- Exhaust Head Design

- How float drain traps work, installation and maintenance

- How to identify a Wright-Ausin Separator

- How to Size a Moisture Separator

- Steam Traps vs. Steam Separators

- Efficiencies of Centrifugal Separators

- Understanding Sizing Factors For Gas/Liquid Separators

- Horizontal

- Vertical

- High Solids

- Coalescer

- Elements

- Exhaust Heads

- Float drain traps

- Liquid level gauges

- Sizing Calculators

- Inquiries

Centrifugal Separators for High Volume Liquid Removal with 99% Efficiency

Wright-Austin TS style gas/liquid separators are designed to remove entrained liquid and solids from air, steam or industrial gasses. The TS style centrifugal separator is based upon the type T design except its body is longer to increase the reservoir size for the separated liquid. This specific design is effective for applications where the entrained liquid droplets separated are ≤ 60% of the separators maximum flow capacity. Droplet separation is accomplished without complex baffles, deflectors and other structures that obstruct the flow-stream and this results in low pressure drops. The TS centrifugal separator design has no moving or serviceable components; it is considered self-cleaning and maintenance free for its entire service life.

Moisture laden gas enters the separator body and is deflected downwards in the cylindrical body, resulting in a powerful vortex. The associated centrifugal force acts upon droplets and particles larger than 10 microns to propel them towards the inner walls of the vessel. Only dry gas and finer droplets enter the lower velocity section of the vortex which is connected to the outlet nozzle. The separated droplets coalesce to a common drain port with re-entrainment prevented by a finned vortex containment plate (VCP). TS centrifugal separators are 99% efficient for removal of entrained droplets and particles larger than 10 microns.

Centrifugal separators are sized based upon five design criteria (molecular weight of gas, highest temperature, lowest pressure, flow rate, volume of liquid to be removed) and maintain their efficiency at lower flow rates and temperatures as related to applications with start-up and shut down conditions.

TS style gas/liquid separators are typically used for

applications where higher than normal liquid loading causes a

"slugging" problem, common to refinery and chemical plant

applications. TS gas/liquid separators are also used upstream of

gas turbines, adsorption towers, gas scrubbers and steam generator

outlets.

TS style gas/liquid separators are typically used for

applications where higher than normal liquid loading causes a

"slugging" problem, common to refinery and chemical plant

applications. TS gas/liquid separators are also used upstream of

gas turbines, adsorption towers, gas scrubbers and steam generator

outlets.

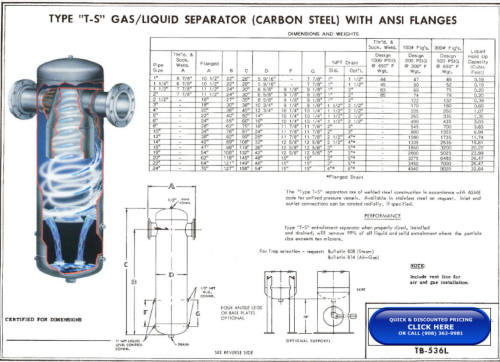

TS air liquid separators are constructed to ASME code for unfired vessels, Section VIII, Division 1. An ASME stamp and CRN registration is available for sizes 2 inches and larger. TS style gas/liquid separators are fabricated from carbon steel, 304SS, 316SS and can also be fabricated from exotic alloys when needed.

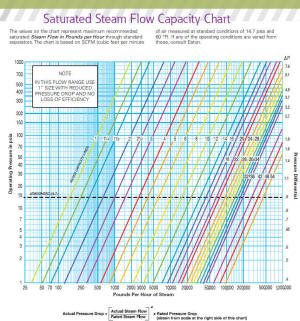

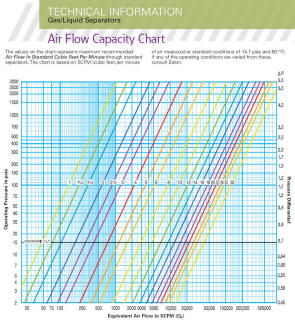

Unless your application involves saturated steam or compressed air at 60ºF, sizing centrifugal separators requires complex calculations because the original sizing charts are based upon tests with steam and compressed air at 60ºF. The calculations required yield the equivalent flow rate of air at 60ºF to correspond with the provided sizing charts. While we have links to the steam and air capacity charts as well as the conversion formulas below, our web-based centrifugal separator sizing calculator will provide the calculations within seconds and makes it easy to compare several separator sizes and designs.

As a custom fabricated vessel, Wright-Austin TS separators can be provided with a corrosion allowance, support legs, lifting lugs, special NDE/NDT, special coatings, inspection ports and reduced connection nozzles. The outline drawing link below provides approximate weights and dimensions applicable to both carbon steel and stainless steel construction.

Wright-Austin Type TS Gas-Liquid Separator Drawing (Click to open PDF file)